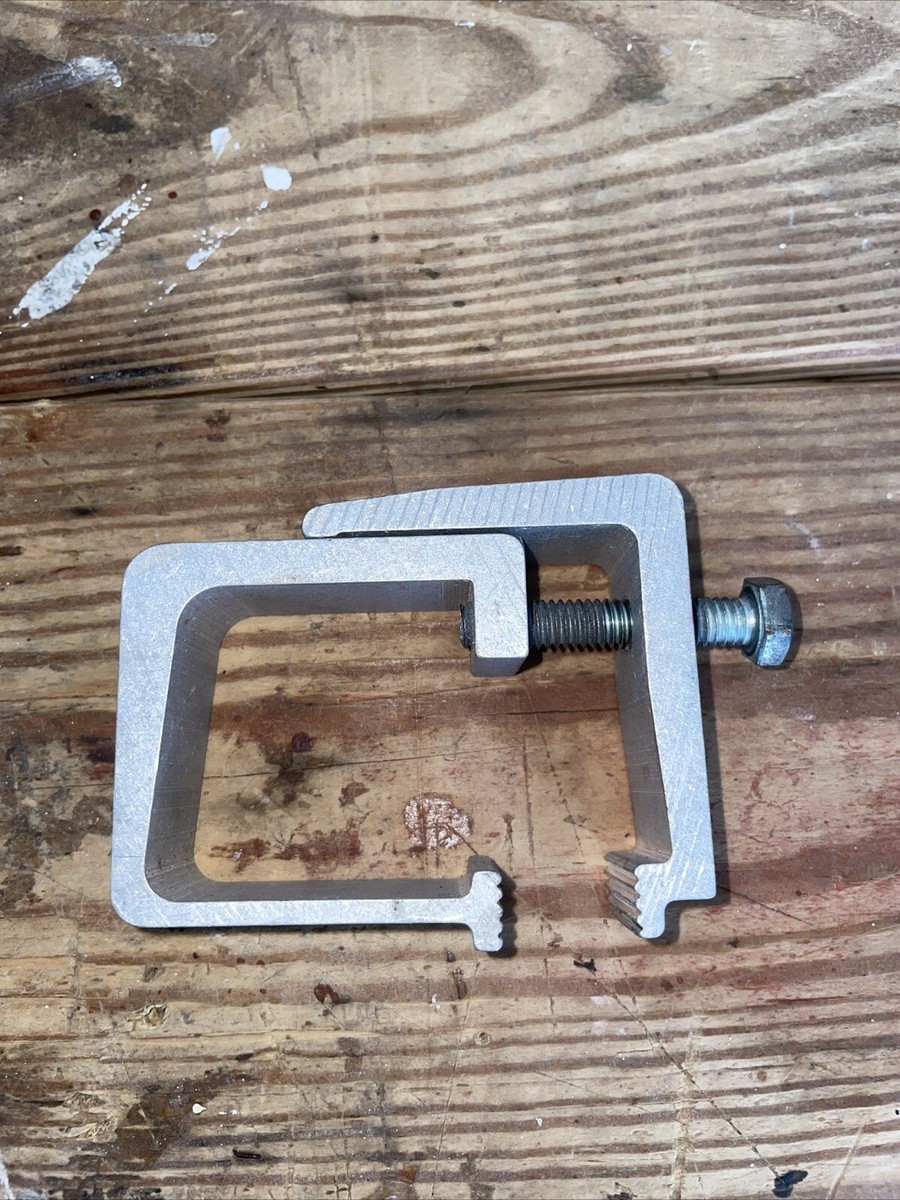

Have you ever considered how a simple clamp can secure your precious cargo in place seamlessly? Truck tonneau cover clamps are the unsung heroes that ensure your belongings remain safe and protected during transit, offering peace of mind with every journey. This often overlooked component plays a pivotal role in maximizing the functionality of your truck bed, ensuring that the tonneau cover fits snugly and securely.

Historically, truck tonneau cover clamps have evolved from basic, rudimentary designs to sophisticated mechanisms that cater to a variety of truck models and covers. These clamps not only provide a secure hold but also contribute to fuel efficiency by improving aerodynamics, potentially saving up to 10% on fuel costs. For professionals constantly on the go, quality clamps mean fewer worries and enhanced security, making them an indispensable part of modern trucking.

Truck tonneau cover clamps are essential for securing the cover to the truck bed, ensuring protection and security of the cargo. These clamps come in various materials like aluminum and steel, offering durability and strength. Proper installation and regular maintenance enhance their effectiveness and longevity, making them vital for any tonneau cover setup.

Exploring the Functional Diversity of Truck Tonneau Cover Clamps

Truck tonneau cover clamps come in various types, each designed to suit specific needs. From simple, manual clamps to more advanced locking mechanisms, these clamps ensure your tonneau cover stays securely in place. This diversity allows truck owners to choose clamps that best fit their usage and preferences. Some are easy to install, while others offer enhanced security features.

One of the most common types is the aluminum tonneau cover clamp. These clamps are durable and lightweight, making them a favorite among truck enthusiasts. They resist corrosion and provide a firm hold. On the other hand, heavy duty truck cover clamps are designed for rougher conditions and provide maximum strength and reliability. This type is ideal for trucks that frequently travel off-road.

Another important category is universal tonneau cover clamps. These clamps are versatile and can fit a wide range of truck models and cover types. They are perfect for truck owners who might switch between different covers or have multiple vehicles. Their adaptability makes them a cost-effective option. Additionally, some models feature quick release mechanisms for added convenience.

Proper installation of tonneau cover clamps is crucial for their effectiveness. It is essential to follow the manufacturer’s guidelines and ensure that the clamps are tightly secured. Using a truck cover clamp kit can simplify this process, providing all the necessary components in one package. Regular maintenance and inspection help prolong the life of the clamps and ensure they function correctly. Proper care ensures that your truck bed covers remain secure and efficient.

etrailer | Replacement Mounting Clamps for TruXedo Tonneau Covers: The Breakdown

Overview of Tonneau Cover Clamps

Tonneau cover clamps are crucial for securing truck bed covers to the vehicle. They ensure that your cover stays firmly in place, protecting your cargo from the elements and potential theft. These clamps are simple to use, yet they provide significant benefits. Truck owners rely on them for both safety and security. Properly installed clamps can also enhance the aerodynamics of your truck.

There are various types of tonneau cover clamps available. Locking clamps are popular because they offer extra security for your cargo. Quick release clamps are another type, designed for easy removal and reinstallation of the cover. Some clamps are made specifically for certain brands and models, like Chevy Silverado or Ford F-150. Universal clamps, on the other hand, can fit almost any truck.

Materials used in making tonneau cover clamps often include aluminum and steel. Aluminum clamps are lightweight but strong, making them a good choice for many truck owners. Steel clamps offer higher durability and strength. Each material has its benefits, and the right choice depends on your specific needs. Both types are designed to withstand harsh weather conditions.

Using a clamp kit can simplify the installation process. These kits come with everything you need for a seamless setup. Following the instructions carefully ensures the clamps are properly installed. Regular checks and maintenance can keep your clamps in top condition. Inspecting them for any signs of wear and tear will help extend their lifespan.

The Crucial Role of Clamps in Tonneau Setup

Clamps play an essential role in securing a tonneau cover to a truck bed. Without these clamps, your cover wouldn’t stay in place, leaving your cargo exposed and vulnerable. They ensure a tight fit, preventing water and dirt from entering the bed. This keeps your belongings safe and dry. A properly installed clamp also improves fuel efficiency by reducing wind drag.

Each type of clamp offers unique benefits. For example, locking clamps add an extra layer of security, deterring potential thieves. Quick release clamps make it easy to access the truck bed whenever necessary. This blend of security and convenience makes clamps a vital component of any tonneau cover setup. Universal clamps provide flexibility for different truck models and brands.

Proper alignment and installation of clamps affect the overall performance of the tonneau cover. Misaligned clamps can cause the cover to warp or loosen over time. This can lead to leaks or the cover coming off during transit. Regular maintenance and adjustments help keep the clamps in optimal condition. It’s crucial to check them periodically for wear and tear.

Investing in high-quality clamps can save you a lot of trouble in the long run. Durable materials like aluminum and steel offer longevity and dependability. They withstand harsh weather conditions and constant use. Clamps made from these materials can be more reliable. This means fewer replacements and peace of mind for truck owners.

Types of Tonneau Clamps Used in Various Truck Models

There are several types of tonneau clamps designed to fit various truck models and brand specifications. Some clamps are customized to fit specific truck beds, like those for a Chevy Silverado or a Ford F-150. These specialized clamps ensure a perfect fit and optimal performance. On the other hand, universal tonneau cover clamps can be adjusted to fit almost any truck model. These provide flexibility and convenience for truck owners with different needs.

Locking clamps are widely used for their added security features. These clamps include lock mechanisms that prevent unauthorized access to the truck bed. They are particularly popular among truck owners who carry valuable cargo. For truck owners seeking easy access to their cargo, quick release clamps are ideal. These clamps allow for fast and simple removal of the tonneau cover when needed.

Material composition also distinguishes different clamp types. Aluminum tonneau cover clamps are lightweight yet strong, making them a popular choice. They resist rust and corrosion, ensuring durability even in harsh weather conditions. Steel clamps, although heavier, offer superior strength and longevity. Both materials are engineered to provide optimal performance based on the user’s requirements.

Heavy-duty truck cover clamps are designed for more rugged applications. These clamps provide extra strength and stability, making them perfect for off-road adventures. They are built to withstand significant wear and tear, ensuring the tonneau cover remains securely in place. This type of clamp is essential for trucks that frequently encounter challenging environments.

For those who frequently change their truck bed covers, using a truck cover clamp kit can be very beneficial. These kits typically include all the necessary components for both installation and replacement. They simplify the process and ensure compatibility with different cover types. Such kits are a practical solution for truck owners who need flexibility and ease of use.

Installation Tips for Securely Fitting Cover Clamps

Begin by ensuring the truck bed is clean and free from debris. A clean surface helps the clamps hold better and prevents damage to the finish. Place the tonneau cover on the truck bed, aligning it properly with the bed rails. This preliminary step sets the foundation for a secure fit. Always double-check the alignment before tightening the clamps.

Using a clamp kit makes the installation process easier. These kits come with all the necessary parts, including screws and brackets. Follow the instructions provided in the kit for the best results. Each kit might have different specifications, so reading the manual beforehand is crucial. Kits designed for specific truck models will provide the best fit.

Tighten the clamps gradually, alternating from one side to the other. This ensures even pressure distribution and prevents warping of the cover. Avoid overtightening, as this might damage the clamps or the truck bed. Use a torque wrench if available. Properly tightened clamps will keep the cover secure without causing strain.

Regularly inspect the clamps to ensure they remain tight and in good condition. Over time, vibration and road conditions might cause them to loosen. Tighten any loose clamps immediately to avoid potential issues. Clean the clamps periodically to remove dirt and grime. This preventive maintenance can significantly extend the lifespan of your clamps.

For added security, consider using locking clamps. These clamps provide extra peace of mind by preventing unauthorized access to your truck bed. They are particularly useful for securing valuable cargo. Locking clamps also help deter theft during stops. Investing in high-quality locking clamps can enhance the overall security of your tonneau cover.

Maintenance Practices for Longevity and Performance

Regular maintenance of your tonneau cover clamps ensures their long-term performance. One of the simplest ways to maintain these clamps is through periodic inspection. Check for any signs of wear and tear, such as rust or loosening. Tighten any loose clamps to keep your cover secure. This routine check helps catch issues early before they become major problems.

Cleaning the clamps is another essential maintenance practice. Dirt and grime can accumulate, affecting their grip and functionality. Use mild soap and water to clean the clamps and dry them thoroughly. Avoid harsh chemicals that can corrode metals. This keeps the clamps in good condition and extends their lifespan.

Lubricating moving parts of the clamps can enhance their performance. Apply a small amount of lubricant to the joints and mechanisms. This reduces friction and makes it easier to adjust the clamps when needed. Choose a lubricant that is appropriate for metal parts to avoid damage. Regular lubrication ensures smooth operation and prevents squeaking.

Store your truck in a covered area whenever possible to protect the clamps from harsh weather. Exposure to elements like rain, snow, and extreme sun can degrade the clamps over time. If garage storage isn’t an option, consider using a weatherproof truck cover. This adds an extra layer of protection and keeps your clamps in optimal condition.

Using a tonneau cover regularly, ensure that the clamps are part of the maintenance routine. Neglecting the clamps can lead to problems with the cover itself. Establish a maintenance schedule that includes both visual inspections and mechanical checks. This proactive approach saves time and resources in the long run. A well-maintained tonneau cover and clamps will perform better and last longer.

Common Issues and Troubleshooting Cover Clamps

One common issue with tonneau cover clamps is loosening over time. This can happen due to vibrations from driving or changes in temperature. Regularly checking the tightness of each clamp can prevent this problem. If you find a loose clamp, tighten it immediately to ensure your cover stays secure. Using a torque wrench can help achieve the correct tension.

Sometimes, clamps may not align properly with the truck bed rails. Misalignment can cause the cover not to fit snugly, resulting in gaps that let water and dirt in. To fix this, adjust the position of the clamps until they line up correctly. It might take a bit of trial and error, but proper alignment is crucial for optimal performance. Double-checking the alignment before securing all clamps can save time.

Rust is another frequent issue, especially for steel clamps exposed to moisture. Rust weakens the clamps and affects their grip. To prevent rust, regularly clean and dry your clamps. Applying a rust-resistant coating can also help protect them from corrosion. If a clamp is already rusty beyond repair, replacing it with a new one is the best solution.

Clamps can sometimes fail to lock securely if their mechanisms are worn out or obstructed by debris. To troubleshoot this, clean out any dirt or particles in the locking mechanism using a small brush or compressed air. Lubricating moving parts will also help maintain smooth operation. If these steps don’t resolve the issue, consider replacing faulty locking clamps with new ones for better security.

Lastly, broken or missing parts are another concern for tonneau cover clamps. Always inspect your hardware when performing regular maintenance checks. Replace any damaged parts promptly to ensure continued functionality of your tonneau cover system.

Materials Used in Manufacturing Tonneau Cover Clamps

Tonneau cover clamps are made from various materials, each offering unique benefits. Aluminum is one of the most popular choices because it’s lightweight and resistant to corrosion. This makes it ideal for truck accessories that need to endure various weather conditions. Aluminum clamps are easy to handle and install. They provide a strong grip without adding excessive weight.

Steel is another common material used in tonneau cover clamps. Steel clamps are known for their exceptional strength and durability. They can withstand heavy loads and harsh environments. However, steel is more prone to rust, so many steel clamps are coated with a rust-resistant finish. This prolongs their lifespan and maintains their functionality.

- Aluminum: Lightweight and corrosion-resistant, perfect for general use.

- Steel: Strong and durable, best for heavy-duty applications.

- Stainless Steel: Combines strength with corrosion resistance.

- Plastic: Good for light-duty applications and cost-effective options.

Stainless steel clamps offer a balance between strength and corrosion resistance. They are heavier than aluminum but provide more durability in corrosive environments. These clamps are often used in coastal areas or places with high humidity. Stainless steel is also aesthetically pleasing, giving a polished look to your truck accessories. It’s a reliable option for those needing both longevity and performance.

Plastic clamps are also available, primarily for lighter-duty applications. While not as strong as metal clamps, plastic clamps are resistant to rust and generally cheaper. They are easy to install and replace. Plastic clamps are suitable for temporary or less demanding situations. They are often used in conjunction with other, more robust clamps for additional support.

Comparative Analysis of OEM vs Aftermarket Clamps

When it comes to truck tonneau cover clamps, choosing between OEM and aftermarket options can be challenging. OEM stands for Original Equipment Manufacturer, meaning these clamps are produced by the same company that made your truck. They are designed to fit perfectly with your vehicle, ensuring compatibility and reliability. On the other hand, aftermarket clamps are made by third-party manufacturers. These usually offer a range of options at different price points.

One significant advantage of OEM clamps is their guaranteed fit and finish. Since they are specifically made for your truck model, installation is straightforward and hassle-free. However, OEM clamps tend to be more expensive. The higher cost often reflects the quality and precision that comes with manufacturer-produced parts. For many, the peace of mind that comes with OEM parts justifies the price.

Aftermarket clamps, however, provide more variety in terms of materials and features. You can find clamps made from different materials like aluminum, stainless steel, and even plastic. This allows for customization based on specific needs and preferences. Additionally, aftermarket options can often be more affordable. They are ideal for truck owners looking to save money while still getting reliable products.

| Feature | OEM Clamps | Aftermarket Clamps |

|---|---|---|

| Fit and Compatibility | Perfect Fit | Varies by Manufacturer |

| Cost | Generally Higher | More Affordable Options |

| Variety | Limited | Wide Range |

| Quality Assurance | Guaranteed | Depends on Brand |

Quality is another essential factor to consider. OEM clamps usually come with a warranty and quality assurance from the truck manufacturer. This guarantees the product’s performance and longevity. Meanwhile, the quality of aftermarket clamps can vary. It’s crucial to research and choose reputable brands to ensure reliability.

In summary, both OEM and aftermarket clamps have their pros and cons. Your choice depends on your budget, specific needs, and preferences. While OEM clamps offer guaranteed fit and quality, aftermarket clamps provide variety and potential cost savings. Weighing these factors can help you make the best decision for your truck.

Impact of Tonneau Clamps on Truck Aesthetics and Functionality

Tonneau clamps play a significant role in enhancing the overall aesthetics of a truck. They ensure that the cover fits snugly, providing a sleek and streamlined appearance. A well-fitted tonneau cover can transform the look of your truck, making it appear more polished and professional. This visual upgrade can increase the truck’s appeal. High-quality clamps contribute to this seamless look.

Functionality is another crucial aspect where tonneau clamps make a difference. They secure the cover firmly, protecting the cargo from weather elements and theft. A firmly clamped tonneau cover also improves aerodynamics, reducing wind drag. This, in turn, can lead to better fuel efficiency. Properly functioning clamps ensure that the cover remains stable, even at high speeds.

The choice of materials for clamps can also impact both aesthetics and functionality. Aluminum and stainless steel clamps offer a sleek, modern look while providing strong performance. These materials are resistant to rust and corrosion, maintaining their appearance and functionality over time. The right clamps can enhance the overall durability of the tonneau cover system. This means fewer replacements and long-term cost savings.

Tonneau clamps also affect ease of use. Features like quick-release mechanisms allow for fast cover removal and installation. This convenience is beneficial for truck owners who frequently access their cargo. Locking clamps add another layer of functionality by providing added security. These features enhance the user experience, making the tonneau cover system more versatile.

Moreover, the visibility of clamps can vary based on their design and placement. Some clamps are designed to be discreet, blending seamlessly into the truck’s design. Others are more prominent but designed to complement the truck’s aesthetics. Whether visible or hidden, the right clamps can enhance the truck’s overall look while ensuring functionality. Choosing the right clamps can improve both the aesthetic and practical aspects of your truck.

Key Considerations When Choosing Tonneau Clamps

When selecting tonneau clamps, material is a top consideration. Aluminum clamps are lightweight and resistant to rust, making them a popular choice. Steel clamps, although heavier, offer greater strength and durability. Both materials have their advantages depending on your needs. Durability and weather resistance are crucial for long-term use.

Compatibility with your specific truck model is another important factor. Some clamps are designed to fit only certain brands and models. Universal clamps offer more flexibility but may not provide a perfect fit. Always check the compatibility before making a purchase. This ensures a secure and snug fit for your tonneau cover.

Ease of installation can make a significant difference. Quick-release clamps are user-friendly and save time, making them ideal for those who frequently remove their covers. Locking clamps add security but may be more complex to install. A clamp kit with all necessary components can simplify the process. Installation should be straightforward to avoid future frustrations.

Cost is another factor to consider when choosing tonneau clamps. OEM clamps are generally more expensive but offer reliable quality and fit. Aftermarket clamps can be more affordable and provide various options. However, the quality can vary, so it’s essential to read reviews and choose reputable brands. Balancing cost with quality ensures you get the best value.

Additional features like locking mechanisms can enhance security and functionality. Look for clamps that offer these added benefits. They provide peace of mind when you leave your truck unattended. Special features can improve both convenience and security. Always weigh these extras when making your final decision.

Lastly, consider the aesthetic impact of the clamps. Some clamps are designed to be discreet, while others may be more visible. Choose a style that complements your truck’s appearance. The right clamps can enhance the overall look of your vehicle. A balance of functionality and aesthetics ensures a satisfying purchase.

Technological Advances in Tonneau Clamp Design

Recent technological advances have significantly improved tonneau clamp designs. One major development is the use of lightweight, high-strength materials like aluminum alloys and reinforced plastics. These materials not only reduce the overall weight but also enhance the durability of the clamps. This ensures they can withstand harsh weather and rugged conditions. These innovations make the clamps more reliable and long-lasting.

Another advancement is the integration of quick-release mechanisms. These allow truck owners to easily remove and reattach their tonneau covers with minimal effort. This feature is especially useful for those who frequently access their truck beds. Quick-release clamps save time and provide convenience. They have become a popular choice for modern trucks.

Some clamps now feature built-in locks for added security. These locks help prevent unauthorized access to the cargo area. This added security is particularly beneficial for truck owners who carry valuable items. The built-in locks eliminate the need for additional security devices. This innovation enhances both safety and functionality.

Advanced design software has also played a role in improving tonneau clamp designs. Engineers use these tools to create clamps that fit more precisely and perform better. This results in products that are tailored to specific truck models. The precise fit enhances the overall performance of the tonneau cover system. This level of customization is a significant advancement.

Smart materials are another exciting development in clamp technology. These materials can respond to environmental changes, such as temperature and moisture levels. They can adapt to different conditions, providing optimal performance at all times. This cutting-edge technology makes clamps more versatile and efficient. It represents the future of tonneau clamp design.

Recommended Accessories and Complementary Products for Tonneau Covers

Tonneau covers benefit greatly from a variety of accessories that enhance their functionality and appearance. One useful accessory is a bed liner, which protects the truck bed from scratches and dents. Bed liners also make it easier to keep the truck bed clean. Another essential product is a tailgate seal, which keeps water and dust out of the truck bed. These seals improve the overall effectiveness of your tonneau cover by providing additional protection.

Cargo management systems are another set of helpful products. These systems include items like cargo nets, bed dividers, and storage boxes.

- Cargo nets secure loose items, preventing them from shifting during transit.

- Bed dividers help organize the cargo area, making it easier to access your belongings.

- Storage boxes provide secure compartments for valuable items, keeping them safe and dry.

These systems can greatly improve the utility of your truck bed.

For increased security, consider investing in locking mechanisms. Locking tailgate handles and additional security locks for your tonneau cover can deter theft. These products are especially important if you carry valuable cargo. An investment in security accessories provides peace of mind. These locks are easy to install and offer robust protection for your truck bed.

LED bed lighting is another useful addition for those who access their truck bed frequently at night. These lights illuminate the truck bed, making it easier to find and organize cargo in the dark. LED strips are energy-efficient and can be installed along the bed rails. They provide ample light without drawing much power. This makes nighttime use of the truck bed more convenient and safer.

Finally, bed extenders can add versatility to your truck bed. These extenders increase the usable length of the bed when the tailgate is down. They are perfect for hauling longer items that wouldn’t fit with the tailgate closed. Bed extenders are easy to install and can be removed when not in use. This flexibility makes them a valuable accessory for any truck owner.

Frequently Asked Questions

Here are some common questions and detailed answers about truck tonneau cover clamps to help you understand their importance and usage better.

1. What materials are commonly used to make tonneau cover clamps?

Tonneau cover clamps are typically made from materials like aluminum, steel, and plastic. Aluminum is favored for its light weight and resistance to rust, making it ideal for various weather conditions. Steel offers greater strength and durability but is heavier and can be prone to rust without a protective coating. Plastic clamps are generally used for lighter-duty applications and are resistant to corrosion. Choosing the right material depends on your specific needs. If you need something lightweight and rust-resistant, aluminum is a good choice. For more strength and durability, steel is better, especially if it has a rust-resistant coating. Plastic clamps are suitable for less demanding conditions and offer an affordable option.

2. How do improper clamp installations affect the tonneau cover?

Improper clamp installations can lead to several issues with your tonneau cover. If the clamps are not tightly secured, the cover might not fit snugly, allowing water and dirt to enter. This can damage your cargo and the truck bed over time. Loose clamps can also cause the cover to flap in the wind, which can be noisy and distracting while driving. Additionally, misaligned clamps can warp the cover, affecting its aerodynamic efficiency and potentially increasing fuel consumption. Regularly checking and ensuring proper installation of the clamps can prevent these issues. It's crucial to follow the manufacturer's guidelines for installation to keep the cover secure and effective.

3. Are aftermarket clamps as good as OEM clamps?

Aftermarket clamps can be just as good as OEM (Original Equipment Manufacturer) clamps, depending on the manufacturer and quality. OEM clamps are designed specifically for your truck model, ensuring a perfect fit and reliable performance. However, they tend to be more expensive. Aftermarket clamps offer a broader range of options in terms of materials and features, often at a lower price. The key is to choose aftermarket clamps from reputable brands. Reading reviews and doing some research can help you find quality aftermarket options that meet your needs. If you prioritize cost and customization, aftermarket clamps are a viable option, while OEM clamps are ideal for those seeking guaranteed fit and reliability.

4. Can locking clamps enhance the security of my truck bed?

Yes, locking clamps significantly enhance the security of your truck bed. These clamps come with built-in locking mechanisms that deter theft by preventing unauthorized access to your cargo area. Locking clamps are especially beneficial if you transport valuable items in your truck bed. They add an extra layer of security, giving you peace of mind when you leave your truck unattended. Installing locking clamps is a straightforward process, and they offer a seamless way to secure your tonneau cover without requiring additional locks. The added security feature is an investment in protecting your belongings and ensuring the safety of your cargo. Look for high-quality locking clamps to maximize the security benefits.

5. How often should tonneau cover clamps be inspected and maintained?

Tonneau cover clamps should be inspected and maintained regularly to ensure they remain in good condition. It's recommended to check the clamps at least once a month for signs of wear, rust, or loosening. Regular inspections help identify potential issues early, allowing you to address them before they become serious problems. Tightening loose clamps and cleaning them can prolong their lifespan and maintain their functionality. If you frequently drive in harsh conditions or on rough terrain, you might need to inspect the clamps more often. Keeping a close eye on the clamps is crucial for maintaining the security and effectiveness of your tonneau cover. Regular maintenance also includes cleaning the clamps to remove dirt and grime, which can affect their performance over time.

All You Need to Know About the Replacement Mounting Clamps for TruXedo TruXport Tonneau Cover

Conclusion

Truck tonneau cover clamps are a vital component for securing your cover and protecting your cargo. They come in various materials and designs, each offering unique benefits. Proper installation and regular maintenance ensure they perform optimally. Investing in quality clamps enhances both the functionality and aesthetics of your truck.

Whether choosing OEM or aftermarket options, the right clamps can make a significant difference. By considering factors like material, fit, and additional features, you can select the best clamps for your needs. Advanced designs and technological improvements continue to enhance their capabilities, making them indispensable for modern truck owners.